A Metal Fireproof Door is a steel door and frame assembly that’s tested, labeled, and installed to slow the spread of fire and smoke for a defined time.

You’ll see these doors in stairwells, corridors, mechanical rooms, and other openings that protect escape routes or separate hazards.

If you want a quick visual overview, watch the video below.

Watch the metal fire door overview video

What is a metal fireproof door and how does it differ from standard metal doors?

A standard hollow metal door can be strong and durable, but that does not make it fire-rated.

A true fire-rated opening is an assembly, door leaf, frame, hinges, closer, latch, and (when required) smoke gasketing, all meant to work together.

Here are the differences that matter on a job site:

- Labeling: Fire-rated doors carry a listing label that identifies the rating and the approved construction.

- Smoke control options: Some openings require smoke and draft control performance, which is commonly tied to UL 1784 testing and an “S” marking on the label.

- Clearances: The gap around the door is limited for fire performance. A common reference point is up to 1/8 inch at the head and jambs, and up to 3/4 inch at the bottom (depending on conditions and the listing).

- Self-closing and self-latching: A fire door has to close and latch reliably, or it will not do its job during an emergency.

I have installed and inspected hundreds of doors in NYC schools since 2000, says Alex Fedin, licensed General Contractor.

In practice, the biggest mistake I see is treating a “metal door” like it’s automatically a “fire door.” It isn’t.

If the label, hardware, and clearances don’t line up, inspectors can treat the opening as noncompliant, even if the door feels heavy and looks new.

Where are metal fireproof doors required by code in NYC?

NYC typically requires fire-rated door assemblies anywhere the plans call for a rated wall, shaft, stair enclosure, corridor separation, or other fire and smoke barrier.

The rules are enforced through permits and inspections, with oversight by City agencies. The NYC Building Code and Fire Code overview is a useful starting point when you want the official language.

If you live in a multi-family building, pay special attention to corridor and stair doors. These doors often need to self-close and self-latch as part of the building’s fire protection strategy.

In a recent HPD update covering Fiscal Year 2025, the agency reported 72,714 self-closing door violations and more than $6.7 million spent facilitating repairs that owners did not complete on their own. Those numbers are why I tell owners and co-op boards to treat door closers and latching as a priority maintenance item, not a “nice to have.”

Why are fire-rated doors critical in schools and public buildings?

Schools and other public buildings move a lot of people through corridors and stairs every day.

Fire-rated doors protect those routes by keeping fire and smoke out of the path of travel long enough for people to exit.

New York City’s focus on self-closing doors became even more visible after the January 2022 Twin Parks fire, where public reporting emphasized how smoke spread can turn deadly fast when doors fail to close.

For homeowners, the lesson is simple: do not treat a closer, latch, or seal as “optional hardware.” If a rated door does not close and latch every time, it is not protecting the building the way the design intended.

If you see wedges, hooks, or kick-down stops holding a stair or corridor door open, assume it will trigger violations and fix it the right way.

NYC Fire Code Requirements for Metal Fireproof Doors

In NYC, you don’t just “buy a rated door.” You prove compliance with the right rating, the right label, the right hardware, and the right installation.

And you keep it working after the job is done, because maintenance is part of compliance.

For context, FDNY enacted the 2022 New York City Fire Code (Local Law 47 of 2022), and it took effect on April 15, 2022. That update matters because many projects reference the current Fire Code language and enforcement approach.

If you want a quick walk-through, here’s a short video.

Watch a short NYC fire door code walkthrough

What fire ratings are required for school buildings in New York City?

Schools can include several different fire and smoke conditions in one building: corridors, stair enclosures, mechanical rooms, and assembly spaces.

That is why you’ll see a range of door fire-protection ratings used in practice, such as 20 minutes (commonly tied to corridor needs), 45 minutes, 60 minutes, and 90 minutes.

Two details that often get missed during budgeting:

- Temperature-rise doors: Some doors also need a temperature-rise rating to limit heat transfer during the early part of a fire. Common temperature-rise ratings are 250, 450, and 650 degrees Fahrenheit.

- Smoke and draft control: Some corridor or smoke barrier openings need smoke performance tied to UL 1784, and the commonly cited limit is 3.0 cubic feet per minute per square foot of door opening at 0.10 inch of water.

If you are upgrading doors in a school or any high-occupancy space, use the approved drawings and the door schedule to confirm ratings. Guessing here is expensive.

Which NYC DOB regulations apply to fire-rated door installations?

In NYC, you plan around permits, approvals, and inspections, not just materials.

From a process standpoint, DOB uses online tools for filings and inspections, and DOB NOW: Inspections was launched on December 7, 2015, as the City’s online inspection request and routing system.

On the technical side, NFPA 80 is the baseline standard most professionals reference for fire door installation, inspection, testing, and maintenance. That’s why we treat labeling, clearances, and hardware compatibility as “first-pass” checks before we set a single frame.

NFPA 80 standard informationLearn what certified fire door installers do on a project

Certified installers and regular inspections keep doors code-compliant.

Bottom line: you want a documented chain from approved plans to labeled products to verified field installation.

How are metal fireproof doors inspected and approved?

Inspectors focus on what they can verify fast: label, clearances, closer, latch, and any obvious field modifications.

If the door does not close and latch consistently, the assembly fails the basic life-safety purpose, even if every component is technically “rated.”

These are common inspection checkpoints you can use as a homeowner or building manager:

- Label is readable: Do not paint over it, cover it with hardware, or bury it under edge guards.

- Clearances are controlled: Excessive gaps at the jambs, head, or bottom are a common failure point.

- No unapproved field work: Drilling, cutting, or adding non-listed accessories can void the listing.

- Closer and latch work together: A closer that slams or a latch that barely catches is a maintenance call waiting to happen.

On the 355 Doors Project, I kept inspection notes per phase so we could correct patterns fast, like hinge-side sag or painted-over labels, before they spread across the building.

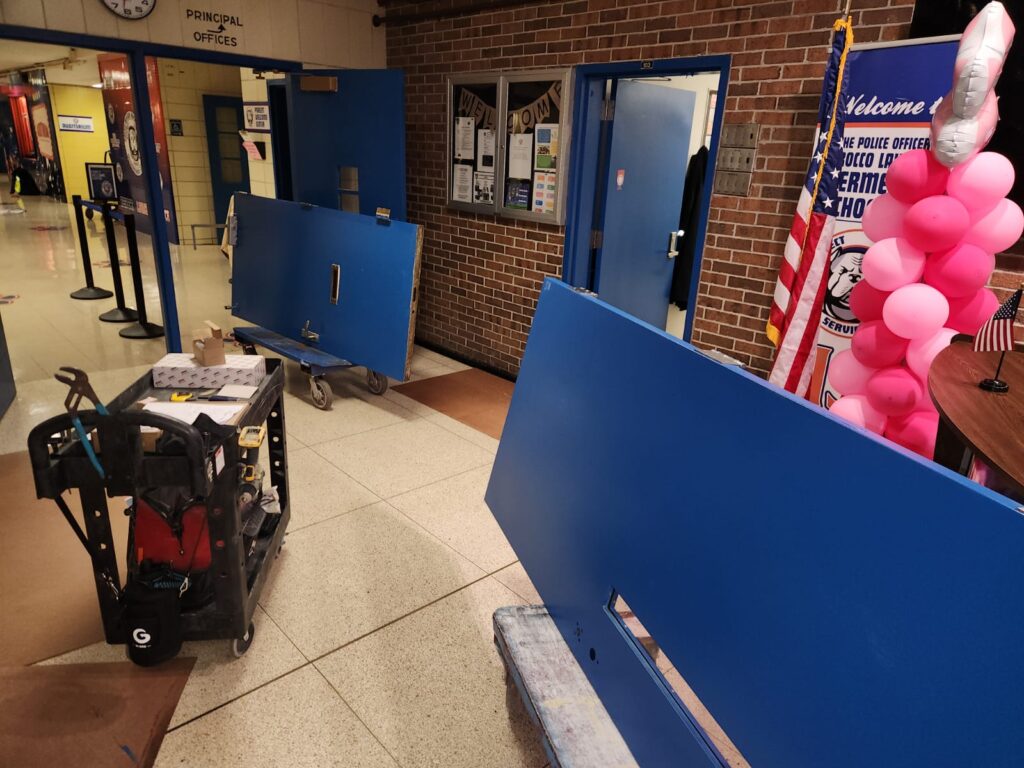

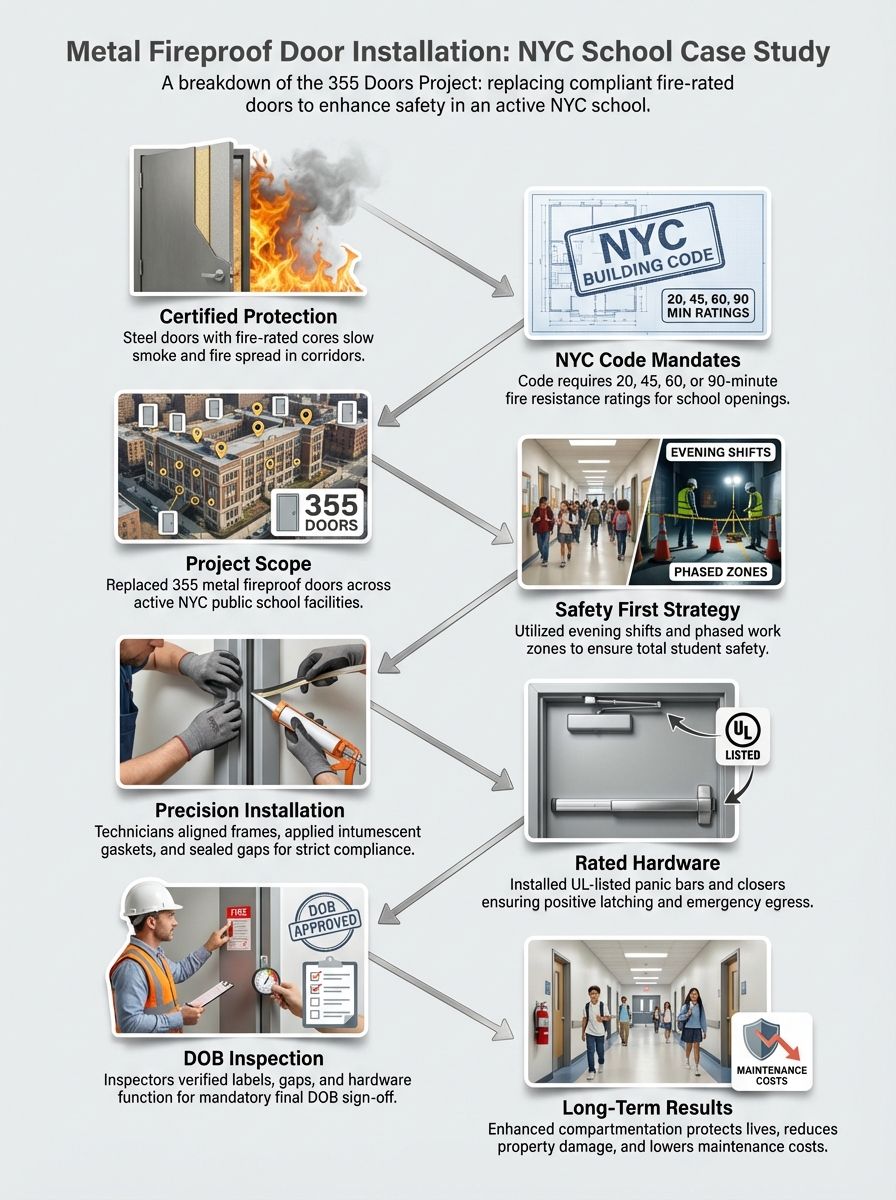

Project Overview: Fireproof Door Replacement in a NYC School

Big door upgrades are never just “a door job,” especially in a building that stays occupied.

In our NYC school project, the goal was clear: replace and upgrade openings so they matched the rated design and could pass inspections with clean documentation.

This section shows what we did, how we scheduled it, and what you can borrow from the approach for your own renovation planning.

Key Highlights

- Alex Fedin of HomeRenovation4U led replacement of 355 metal fireproof doors in an NYC school to support DOB and FDNY compliance expectations.

- The project completed in 12 weeks using phased evening and night shifts to limit disruption and maintain safety controls.

- The door schedule used ratings commonly seen in institutional work, including 20, 45, 60, and 90 minutes, matched to the opening location and the approved drawings.

- We treated inspection readiness as part of production, label checks, clearance checks, closer and latch testing, and organized records per phase.

- Seals, closers, and panic hardware were selected to match the labeled assembly and day-to-day traffic demands.

What type of building was involved in this project?

This project took place in a New York City public school.

HomeRenovation4U led the metal fireproof door replacement across the NYC Metro Area, coordinating with the project team to keep work aligned with inspections and safety requirements.

How many metal fireproof doors were replaced in total?

We replaced 355 metal fireproof doors as part of the 355 Doors Project in a New York City school.

When I say “355 doors,” I mean complete openings, door leaf, frame, and the listed hardware and seals that make the assembly perform as rated.

Why was a phased installation approach required?

We phased the job because the building stayed active, and the school needed predictable, controlled work zones.

From a safety standpoint, New York State’s school construction safety standards put responsibility on school personnel to monitor occupied areas during construction or maintenance activities, so you plan the workflow to keep occupied spaces safe and functional.

Our phased plan used a simple rule: remove and replace in small batches, close out punch items immediately, then move to the next zone.

Work Schedule and On-Site Constraints

We scheduled nights and evenings to cut disruption, keep corridors controlled, and move inspectors through clean, staged checkpoints.

If you want to see the type of staging we use, watch the short clip below.

Watch how we staged night work in a school

Why was evening and night work required for this project?

Door replacements hit corridors, stairs, and classroom thresholds, the exact places schools need open during the day.

Evening and night work gave us clear access for tear-out, framing, and hardware testing without mixing crews with student movement.

It also helped with quality control. When you set five or ten openings in a row under consistent conditions, you catch alignment issues early and keep the next phase tighter.

How were students and staff safety maintained during installation?

We treated the job like two sites in one building, an active school and a secured construction zone.

We used controlled access, barrier lines, and clear handoff rules so no one wandered into an open frame or a tool staging area.

- Isolate the work: Close off corridors and keep detours obvious.

- Keep egress clear: Never store doors, frames, or carts in exit paths.

- Control dust and noise: Use low-dust methods where possible and schedule the loud cuts for late hours.

- Document daily: Track which openings are complete, pending, or waiting on inspection.

If your project is in an older building, add environmental checks to planning. NYC schools, for example, publish AHERA-related notices for asbestos management, so you coordinate scope and containment before demolition starts.

What challenges arise when working in active school facilities?

Active school sites force tight schedules and strict routing, because kids move fast and hallways get crowded.

Two constraints show up on almost every institutional job:

- Limited staging: Tight corridors mean you break deliveries into smaller loads and stage by floor.

- Noise windows: You plan cutting, drilling, and frame anchoring for the hours the building can tolerate.

When you plan those constraints early, you avoid the worst-case scenario, removing too many doors at once and scrambling to “make it safe” before morning.

Metal Fireproof Door Installation Process

A clean fire door install is equal parts carpentry and compliance.

You remove the old opening without damaging the wall, set the new frame square, hang the leaf, then prove it closes and latches with the right clearances.

How were existing doors removed and prepared for replacement?

On this school job, we removed existing doors in small batches so corridors stayed predictable and safe.

My removal checklist stayed consistent across the building:

- Remove the leaf and hardware carefully, then separate items that can be reused from items that must be replaced.

- Inspect the existing frame and anchors, then log damage that could distort the new frame alignment.

- Clean and prep the opening so shims, anchors, and fire-rated sealants bond correctly.

- Stage materials off the main path of travel, label by room number, and keep records ready for review.

- Secure the opening during shifts so no one encounters an unprotected frame edge.

What steps are involved in installing metal fireproof doors correctly?

The fastest way to fail a fire door inspection is to rush the frame.

These are the core steps we follow in NYC so the door works, latches, and stays inside its listed tolerances:

- Verify the opening: Measure, check plumb and square, and confirm the selected rated assembly matches the door schedule.

- Set the frame: Shim and anchor so the frame stays square under load, then re-check before final tightening.

- Install required seals: Add intumescent and smoke gasketing only where the listing and the opening require it.

- Hang the door: Install listed hinges, confirm a consistent reveal, and adjust for smooth swing.

- Install hardware: Add closer, latch, lockset or panic hardware per the listing, then test for positive latching.

- Record results: Log label info, clearance checks, and closer settings so future maintenance is straightforward.

How is door alignment and sealing ensured for fire compliance?

Alignment is where craftsmanship meets code. If the gaps are wrong, the seals cannot do their job.

For many labeled assemblies, a practical benchmark is keeping perimeter clearances around 1/8 inch (with limited tolerance based on door type) and keeping the bottom clearance within the listing, often up to 3/4 inch.

When smoke and draft control is required, many labeled “S” door assemblies are tied to UL 1784 air leakage limits, commonly cited as no more than 3.0 cubic feet per minute per square foot of door opening at 0.10 inch of water. Use that requirement to guide whether you need smoke gasketing and a compliant bottom solution.

- Square frame first: Fix the frame, not the door, when reveals are inconsistent.

- Test the closer and latch together: A door that “almost latches” will fail in real use.

- Do not bury labels: Mask labels before painting and avoid hardware that covers identification.

- Re-check after finishing: Paint buildup and new kickplates can change clearances and closing behavior.

Door Frame Restoration and Painting

Painting and frame repair look cosmetic, but they can change how a door closes, latches, and seals.

On a fire-rated opening, a heavy paint buildup can also create friction that slows the closer or prevents full latching.

Why is repainting fire-rated door frames required after installation?

Frames take the most abuse in schools and multi-family buildings, carts, strollers, cleaning machines, and daily traffic.

Repainting protects the metal from corrosion and helps the opening look finished, but you have to do it without compromising the label, gasketing, or clearances.

- Mask the label so it stays readable.

- Keep paint off seals, latching hardware, and closer arms.

- Fix dents and frame twists before you paint, because paint will not correct alignment.

What type of paint and preparation is used for metal frames?

For interior steel frames, the safest approach is to follow the door and frame manufacturer’s prep and coating guidance, and to use products compatible with the existing primer system.

In the field, the prep work tends to decide the outcome more than the brand of paint:

- Clean off oils and residues so the new coating bonds.

- Feather sand chips and rust, then spot-prime bare steel where needed.

- Apply thin, even coats so you do not build up paint on the stops and change the reveal.

- After curing, cycle the door and confirm it still closes and latches without rubbing.

How does frame condition affect fire door performance?

A damaged frame can create gaps that no seal can “fix,” and it can also pull hinges out of alignment so the latch never seats correctly.

For steel door work, I often reference the Steel Door Institute’s SDI 111 details because it breaks out common wall and frame conditions into recommended details, including frame anchors and gasketing and threshold guidance.

If you keep seeing the same problems, like hinge-side sag, split anchors, or twisted stops, you usually need frame repair or replacement, not more adjustment time.

Fire-Rated Hardware Installation

Hardware is what turns a rated slab into a working fire door: it has to self-close and self-latch every time.

In schools and high-traffic buildings, I spec proven product lines because repeated use exposes weak hardware fast.

As of January 2026, online commercial hardware listings commonly show fire-rated panic devices in the four-figure range (for example, Von Duprin 99 series listings around $1,177 to $1,646), with heavy-duty closers like the LCN 4040XP around the mid-$400s. Those price points are a good reality check when you build a renovation budget.

| Hardware type (examples) | Why it matters on a fire door | Typical listed pricing seen online (Jan 2026) |

|---|---|---|

| Panic device (example: Von Duprin 99 series) | Supports fast egress and reliable latching under heavy daily use | $1,177 to $1,646 (device only, common configurations) |

| Surface closer (example: LCN 4040XP) | Helps the door close and latch consistently, which is the core fire function | About $436 |

| Grade 1 cylindrical lever (example: Schlage ND series) | Durability for high-cycle openings like corridors and classrooms | About $360 to $376 (common “less cylinder” options) |

| Grade 1 mortise lock (example: Schlage L series) | Often specified for institutional security and long service life | About $693 to $740 (common functions and trims) |

What hardware is required for metal fireproof doors in schools?

At a minimum, a school fire door opening needs listed hinges, a listed closer (when required by the door function), and latching hardware that secures the door in the closed position.

Many corridor and exit openings also require panic hardware, and some openings require smoke gasketing or specific closer behavior.

The key is compatibility. Every component you add has to be allowed by the door’s listing, or you risk voiding the label.

How are panic bars, closers, and locks selected and installed?

I select hardware the same way I select doors: match the opening’s function first, then match the listing, then match the abuse level.

- Confirm the door function: corridor, stair, classroom, exterior, or mechanical room.

- Pick listed hardware: hardware that is approved for labeled fire door assemblies.

- Choose the right grade: high-traffic openings often call for Grade 1 durability.

- Install to templates: avoid “field creativity” that changes prep or clearances.

- Test and document: closing speed, latch engagement, and any smoke seal contact points.

How does hardware installation affect fire and life-safety compliance?

Fire doors fail in real buildings for simple reasons: the latch does not catch, the closer is disconnected, or someone holds the door open.

In NYC, HPD guidance on self-closing doors is direct about avoiding items that can hold a door open, and NYC Fire Code sections addressing hold-open devices also point back to inspection, testing, and maintenance expectations.

If you need a door to stay open for operations, use an approved releasing method tied to the building’s fire protection strategy. Do not improvise with wedges, hooks, or kick-down stops.

Role of Carpentry and Painting Subcontractors

On large door projects, subs make or break the outcome.

Carpenters set frames and hardware prep correctly. Painters protect the metal without changing clearances or burying labels.

What tasks are handled by carpentry subcontractors in door projects?

Carpentry subs handle removal, frame setting, shimming, anchoring, and coordination so every opening stays plumb and square.

They also support hardware installation by keeping hinge and strike locations clean, consistent, and within the manufacturer’s templates.

- Set frames square and anchored for the wall type.

- Repair openings so shims and anchors hold long-term.

- Coordinate with hardware techs so prep stays within the listing.

How do painting subcontractors ensure durability in high-traffic areas?

Painters protect frames by using compatible coatings and by controlling film buildup on the stops.

In schools and multi-family buildings, we also plan touch-ups as part of turnover, because door frames get hit constantly.

- Mask labels and seals before coating.

- Use thin coats at the stops to avoid rubbing and latch issues.

- Re-test closing and latching after cure.

Why trade coordination is critical in large-scale fire door projects?

One trade can unintentionally undo another trade’s work.

If painters load up the stop with thick paint, the closer may not latch. If hardware techs drill outside the template, the listing can be compromised.

On the 355-door replacement, weekly coordination kept the sequence clean: frame first, hang and align second, hardware third, finish last, then test and document.

NYC DOB Permits and Inspections

DOB oversight is part of any significant NYC renovation that changes building elements tied to life safety.

For door projects, that means you plan the scope, filings, and inspection checkpoints before you order material.

What permits are required for metal fireproof door replacement?

The permit question depends on scope and building type, so you confirm it with your design professional and filing strategy.

From a practical standpoint, you should be prepared to show that each opening matches the approved drawings and that the installed door assemblies are labeled and installed per their listing.

If the scope changes after filing, you plan for a post-approval amendment process so the paperwork matches the field reality.

How does DOB inspection work during multi-phase installations?

Multi-phase jobs work best when every phase is inspection-ready.

DOB NOW: Inspections is the City’s online system for scheduling and tracking inspections, and it standardizes inspector checklists and tracking so you can see pass, fail, and objections clearly.

- Close out one zone at a time.

- Fix repeat issues immediately, then update the crew’s checklist.

- Keep phase documentation organized so you can respond fast to objections.

What is required for final approval and sign-off?

Final approval is about proving the finished work matches the approved scope and meets required inspections.

For door projects, that often means you can produce door schedules, label verification, installation checklists, and any required inspection reports in a clean package.

Owners like this because it makes future maintenance simpler. Inspectors like it because it reduces guesswork.

Project Timeline, Results, and Compliance Outcomes

This project was a large door count in an active building, so the schedule lived or died by phasing and night work.

We kept production steady by standardizing frame set, hang, hardware, test, and document across every zone.

How long did the full installation of 355 doors take?

The 355 Doors Project finished in 12 weeks using phased evening and night shifts.

We kept the timeline predictable by limiting each phase to a manageable number of openings and closing out punch items before moving on.

What safety and compliance improvements were achieved?

Replacing 355 metal fireproof doors strengthened compartmentation, supported safer egress routes, and reduced the risk created by doors that did not reliably close and latch.

The practical win was consistency. Once every corridor and stair opening behaved the same way, daily operations became safer, and maintenance became simpler.

- Better closing and latching consistency across corridors and stairs

- Clearer documentation for inspections and future service

- Reduced door-related hazards like rubbing frames and failed latches

What are the long-term benefits of properly installed metal fireproof doors?

Properly installed metal fireproof doors protect lives by buying time and maintaining safer escape routes.

They also save money long-term by reducing emergency repairs, avoiding repeat violations, and lowering the chance that a small hardware issue turns into a full door replacement.

For NYC homeowners and building owners, the biggest long-term benefit is predictability: doors close, doors latch, and you can prove what you installed.

Conclusion: Planning Your Metal Fireproof Door Upgrade in NYC

If you’re upgrading a Metal Fireproof Door in the NYC Metro Area, focus on the assembly, not just the slab.

Start with the door schedule and the purpose of the opening, then match the label, the hardware, and the clearances to that requirement.

When you do it this way, you pass inspections more smoothly, and you end up with doors that work safely every day, not just on paper.

FAQs

1. What is the 355 Doors Project at this NYC school?

The 355 Doors Project installs metal fireproof doors and matching frames across the school, to raise safety and meet code. The project fits certified doors, approved hardware, and seals for fire resistance.

2. What standards and certification do the doors follow?

Doors follow New York City building rules, NFPA 80 guidance, and third-party certification for fire rating, to ensure compliance and documented performance.

3. How long does a metal fireproof door installation take in an NYC school?

A typical installation takes two to four hours per door, including fitting the frame and hardware, though complex openings take longer.

4. What maintenance and inspection do these doors need after installation?

Inspect door operation, latches, closers, and intumescent strips on a regular schedule, and repair with approved parts when needed. Keep records of inspections and service, to prove ongoing compliance with school safety rules.

References

- https://www.vetrotech.com/education/difference-between-fire-doors-regular-doors

- https://metrocellardoor.com/fire-door-installer-how-to-tell-if-your-fire-door-is-up-to-code-in-nyc/

- https://www.primahousing.com/company/Fire_Rated_Steel_Door_A_Critical_Component_in_Building_Fire_Safety_1409.html

- https://www.nyc.gov/assets/fdny/downloads/pdf/business/nyc-fire-code-guide.pdf (2021-04-28)

- https://metrocellardoor.com/common-fire-code-violations-a-fire-door-installer-in-new-york-city-can-help-you-avoid/

- https://www.realtor.com/advice/home-improvement/passive-house-design-used-to-build-school-and-the-benefits-are-endless/

- https://www.fema.gov/sites/default/files/2020-08/fema426_0.pdf

- https://www.usfa.fema.gov/downloads/pdf/publications/design_of_fire_ems_stations.pdf

- https://www.facebook.com/groups/gettinsaltyfans/posts/3006840972806798/

- https://extapps.dec.ny.gov/data/DecDocs/C224304/Work%20Plan.BCP.C224304.2021-03-22.Final%20RAWP%20Appendices%20C-%20I%20(File%204%20of%204).pdf (2021-03-22)

- https://www.uvm.edu/histpres/HPJ/AndreThesis.pdf

- https://asturmadidoors.com/en/blog/complete-guide-for-the-installation-of-fire-doors/

- https://www.linkedin.com/pulse/correct-installation-method-fire-rated-proof-doors-catherine-wong-gagec

- https://www.usafiredoor.com/everything-you-need-to-know-about-painting-metal-doors/ (2025-09-15)

- https://www.eurolinesteelwindows.com/how-to-paint-a-steel-door-a-step-by-step-guide/

- https://steeldoor.org/wp-content/uploads/2020/05/SDI-Fact-File.pdf

- https://minkelsafeandlock.com/blog/what-materials-are-required-for-compliant-fire-door-installation-in-brooklyn-ny (2025-12-25)

- https://www.dhs.gov/xlibrary/assets/st/bips07_428_schools.pdf

- https://chpexpress.com/wp-content/uploads/2024/10/Seg-21-Astoria-Annex-EMCP_Appx-G_Construction-and-Safety-Policies-and-Procedures.pdf

- https://townofbeekman.gov/wp-content/uploads/2025/08/Beekman-Garage-Door-Replacement-Specification.pdf (2025-08-14)

- https://www.nyc.gov/assets/hpd/downloads/pdfs/services/08a-metal-doors-and-frames.pdf

- https://www.nyc.gov/site/buildings/industry/dob-now-inspection.page

- https://www.nyc.gov/site/buildings/dob/project-requirements-project-sign-off-and-completion.page

- https://www.nyc.gov/assets/buildings/pdf/25crane_report.pdf

- https://extapps.dec.ny.gov/data/DecDocs/C224195/Work%20Plan.BCP.C224195.2015-05-26.B&Z%20Steel%20Final%20Approved%20RAWP.pdf (2015-05-17)